|

Puyang Hongyu Pressure Vessel Co., Ltd.

|

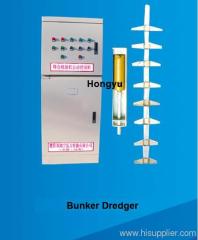

Air cannon

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

also known as the air flow-aiding machine or block clear, is special device for preventing and removing material arching

Product Overview

The built-up and arching of materials in the bunker has already become an inevitable universal malady of all types of bunkers. It is necessary to equip bunkers with a most advanced and ideal device preventing arching and promoting flowing of materials to improve the flow rate of materials in the bunker and to prevent arching, blocking and sticking of materials in the bunker with the most safe, energy-saving and quick method while maintaining the continuity of the production process. A frequent problem in thermoelectric power station is the blocking of raw coal bunker, which harms the raw coal problem in thermoelectric power station is the blocking of raw coal bunker, which harms the raw coal bunker greatly and may leads to output drop of the coal mill or even spontaneous combustion and explosion.

Dredging equipments, like air cannon and dredging machine, manufactured by our company have been widely applied in a lot of power plants. With the significant blocking removal effects, high degree of automation and little maintenance work; it can replace dangerous and money-consuming arch-breaking flow-aiding methods with poor effects, such as manual poking, explosive explosions, mechanical vibration and wearing plate; which can decrease the labor intensity, ensure the production safety, and bring intangible economic benefits. Free of public hazard and pollution, it is recognized as the most advanced economic, optimal, environmental and safest arch-breaking flow-aiding equipment.

Introduction to air cannon

Air cannon, also known as air arch-breaking flow-aiding machine or dredger, eliminates the blocking by a sudden expansion shock wave, generated from the sprayed strong compressed gas with a speed of over I mach (sound velocity), directly blowing the blocked materials. It can resume material flow at one operation without causing the static friction of materials. As the compressed air is spraried like vortex, it is also called vortex blaster. It's a new patent of our company. Applying the aerodynamics, the equipment can convert compressed air into jet kinetic force with strong impct force uding a differential pressure device and automatic-controlled quick exhaust valve in it; so it is a kind of ideal clean and pollutiong-free block-cleaning soot -blowing equipment with low energy consumption.

The euqipment possesses advantages of simple structure strong impact force, safe, energy saving, easy operation with automatic control, and damage free for bunkers.

Features:

● Fast ejecting effectively breaking material bridge and eliminating blocking;

● The combined air cannon with strong applied force;

● Operating almost silently with low noise and no polltion;

● The no-leakage design may effectively utilize the energy;

● Materials in the bunker may not be compressed;

● Required minimal maintenance: remove parts simply, since there are no motors and bearings, there is no need to apply lubrication;

● The strong ejecting force may be applied for wide range effectively;

● The special reset device allows automatic resetting quickly after ejecting to block the materials in the bunker enters the body by mistake;

● The service life is long, and free maintenance is provided for all parts and components within one year.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Cannon Ink Cartridge

Air To Air Heat Exchanger

Air To Air Exchanger

Air Filter

Air Compressor

Air Cylinder

More>>