|

Puyang Hongyu Pressure Vessel Co., Ltd.

|

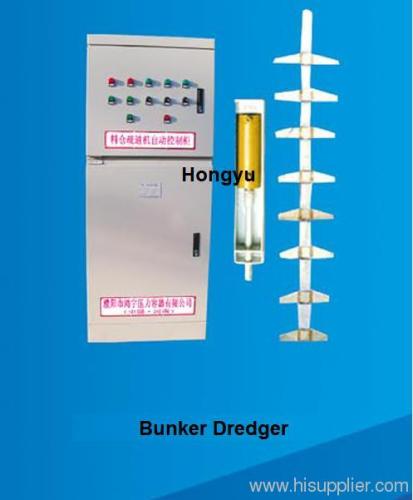

Bunker Dredging Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Overview of Bunker Dredging Machine

Overview of Bunker Dredging Machine

Features

1. ST series bunker dredging device has overcome defects of other dredging forms, such as high strength, small effect, large investment and tank body damage.

2. High Automation: Save coal bunker system layout. The dredging device usually does not work. When the coal bunker cuts off flow due to congestion, the device will dredge and shut down after smooth flow automatically.

3. Dredge Area: The dredge area is 2-6 square meters; the dredge height is 2-3m; the machine will automatically shut down after smooth flow.

4. Energy Conservation: Momentum is greater than 60,000N, while the power consumption is only 3KW.

5. Convenient Installation and Maintenance: Reliable use and high cost efficiency. Under normal circumstances, the hydraulic oil will be replaced every 2 years, namely, years return with once investment.

6. Wide Application: The series dredging device is applicable to different storage containers, such as square tapered, conical, hyperbolic, concrete structure and steel structure warehouses. In addition to coal bunker for coal-fired power plants, it also can be widely applied to similar storage containers in other industries, such as mining, metallurgy, cement, chemicals and construction, etc.

7. Ideal Environmental Protection Effect: This series dredging device adopts high-pressure pumps to drive hydraulic fluid work in a closed loop pipe, so it has no harm, pollution or noise in the course of use.

8. Easy Control (local or remote control); locally, the dredging machine can be started manually and automatically stop after a cycle of action. When remote control is required, dredging machine has an interface with the remote control switch distributed control system (DCS) and the action will automatically stop after a cycle.

9. The action and time of dredging machine will be displayed by the counter.

10. The dredging device has emergency stop button (local or remote) to make operators stop the dredging machine or cut off power at any time.

11. The dredging device has pump motor protection function; when it is overloaded or lacks phase, the electrical control panel will issue &ldquo instructions and carries out automatic power-off reset in 3 seconds. If the machine is overloaded for 3 times within 9 seconds, the motor will cut off power and pump will be stopped. It will start normal work when the start button is pressed after the error is handled.

As domestic electricity, coal, coking and coal chemical industries become larger and automatic, the original coal bucket sizes continue to increase and the requirement for balancing coal supply of coal feeder is increased. In view of this situation, our company has developed a new generation of full-automatic hydraulic dredging device — ST Series bunker dredging machine. The new-generation ST series bunker dredging machine is driven by a hydraulic pump, which will lead scraper in drag hopper of hydraulic tank to do up and down work. The product starts automatically according to the coal lacking signal to dredge materials and stops automatically after the resumption.

Features

1. ST series bunker dredging device has overcome defects of other dredging forms, such as high strength, small effect, large investment and tank body damage.

2. High Automation: Save coal bunker system layout. The dredging device usually does not work. When the coal bunker cuts off flow due to congestion, the device will dredge and shut down after smooth flow automatically.

3. Dredge Area: The dredge area is 2-6 square meters; the dredge height is 2-3m; the machine will automatically shut down after smooth flow.

4. Energy Conservation: Momentum is greater than 60,000N, while the power consumption is only 3KW.

5. Convenient Installation and Maintenance: Reliable use and high cost efficiency. Under normal circumstances, the hydraulic oil will be replaced every 2 years, namely, years return with once investment.

6. Wide Application: The series dredging device is applicable to different storage containers, such as square tapered, conical, hyperbolic, concrete structure and steel structure warehouses. In addition to coal bunker for coal-fired power plants, it also can be widely applied to similar storage containers in other industries, such as mining, metallurgy, cement, chemicals and construction, etc.

7. Ideal Environmental Protection Effect: This series dredging device adopts high-pressure pumps to drive hydraulic fluid work in a closed loop pipe, so it has no harm, pollution or noise in the course of use.

8. Easy Control (local or remote control); locally, the dredging machine can be started manually and automatically stop after a cycle of action. When remote control is required, dredging machine has an interface with the remote control switch distributed control system (DCS) and the action will automatically stop after a cycle.

9. The action and time of dredging machine will be displayed by the counter.

10. The dredging device has emergency stop button (local or remote) to make operators stop the dredging machine or cut off power at any time.

11. The dredging device has pump motor protection function; when it is overloaded or lacks phase, the electrical control panel will issue &ldquo instructions and carries out automatic power-off reset in 3 seconds. If the machine is overloaded for 3 times within 9 seconds, the motor will cut off power and pump will be stopped. It will start normal work when the start button is pressed after the error is handled.

Related Search

Dredging Grab

Packing Machine

Cutting Machine

Printing Machine

Sealing Machine

Filling Machine

More>>